Understanding the Arc Flash Warning Labels

Each piece of equipment operating at 50 volts or more and not put into a de-energized state must be evaluated for arc flash and shock protection. This evaluation will determine the actual boundaries (i.e. prohibited, limited, restricted etc) and will inform the employee of what PPE must be worn.Once the evaluation is complete an Arc Flash Hazard warning label must be affixed to the equipment and readily accessible to employees who may work on the energized equipment.To increase safety and ensure compliance throughout the workplace, it is essential to identify arc flash hazards in your facilities. Arc flash labeling is an important responsibility that should be addressed by the employer and includes the labeling of electrical equipment, such as switchboards, panel boards, industrial control boards, meter socket enclosures and meter control centers.These labels should have relevant information to keep employees safe, including nominal system voltage, arc flash boundary and personal protective equipment information.Minimum arc flash label example Detailed (preferred) arc flash label example

Each piece of equipment operating at 50 volts or more and not put into a de-energized state must be evaluated for arc flash and shock protection. This evaluation will determine the actual boundaries (i.e. prohibited, limited, restricted etc) and will inform the employee of what PPE must be worn.

Once the evaluation is complete an Arc Flash Hazard warning label must be affixed to the equipment and readily accessible to employees who may work on the energized equipment.

To increase safety and ensure compliance throughout the workplace, it is essential to identify arc flash hazards in your facilities. Arc flash labeling is an important responsibility that should be addressed by the employer and includes the labeling of electrical equipment, such as switchboards, panel boards, industrial control boards, meter socket enclosures and meter control centers.

These labels should have relevant information to keep employees safe, including nominal system voltage, arc flash boundary and personal protective equipment information.

Minimum arc flash label example Detailed (preferred) arc flash label example

What Needs to be Labeled?

Arc flash labeling is the responsibility of the employer, not the manufacturer or installer of the equipment. The NEC provides the following examples of electrical equipment that must be field marked with a warning label (This is not an all inclusive list):- Switchboards

- Panel boards

- Motor control centers

- Industrial control panels

- Meter socket enclosures

Labeling is required for any piece of electrical equipment that is likely to require examination, adjustment, service or maintenance while energized, creating the potential for an arc flash incident to occur. Thus, many employers are also labeling bus ducts and other electrical equipment not specifically called out in the NEC (National Electrical Code). Any modifications or renovations to electrical equipment that will change data on the label will require an updated arc flash risk assessment and label according to the 2015 NFPA 70E standard. At minimum, the safety program needs to be audited at intervals not to exceed 3 years and arc flash risk assessment shall be periodically reviewed at intervals not to exceed 5 years. The labeling requirements for equipment installed prior to the 2002 NEC Provision are not specifically stated.

Any modifications or renovations to electrical equipment that will change data on the label will require an updated arc flash risk assessment and label according to the 2015 NFPA 70E standard. At minimum, the safety program needs to be audited at intervals not to exceed 3 years and arc flash risk assessment shall be periodically reviewed at intervals not to exceed 5 years. The labeling requirements for equipment installed prior to the 2002 NEC Provision are not specifically stated.

However, OSHA’s general duty clause for hazard warning may apply here. Should the equipment be modified or upgraded in any way, then a label must be affixed. In fact, an OSHA representative has stated that even changing a fuse or circuit breaker could be considered a modification that would require labeling. Labels applied prior to September 30, 2011 are acceptable if they contain the available incident energy or required level of PPE.From a safety perspective, the hazard is the same regardless of when the equipment was installed. Consequently, most employers are simply labeling all the appropriate equipment, regardless of when it was installed.The NEC requirement states that the marking must be in a location that is clearly visible to qualified persons before they begin work. Typically, the label is placed outside the panel or enclosure door. In some cases,companies choose to put the label inside the door to protect it from harsh environments; however, this should only be done if the door must be opened (allowing the label to be seen) in order to remove the panel face or enclosure. The key point is that the label should be easily noticeable by workers before they may be exposed to any potentially dangerous live parts.

Arc flash labeling is the responsibility of the employer, not the manufacturer or installer of the equipment. The NEC provides the following examples of electrical equipment that must be field marked with a warning label (This is not an all inclusive list):

- Switchboards

- Panel boards

- Motor control centers

- Industrial control panels

- Meter socket enclosures

Labeling is required for any piece of electrical equipment that is likely to require examination, adjustment, service or maintenance while energized, creating the potential for an arc flash incident to occur. Thus, many employers are also labeling bus ducts and other electrical equipment not specifically called out in the NEC (National Electrical Code).

Any modifications or renovations to electrical equipment that will change data on the label will require an updated arc flash risk assessment and label according to the 2015 NFPA 70E standard. At minimum, the safety program needs to be audited at intervals not to exceed 3 years and arc flash risk assessment shall be periodically reviewed at intervals not to exceed 5 years.

The labeling requirements for equipment installed prior to the 2002 NEC Provision are not specifically stated.

However, OSHA’s general duty clause for hazard warning may apply here. Should the equipment be modified or upgraded in any way, then a label must be affixed. In fact, an OSHA representative has stated that even changing a fuse or circuit breaker could be considered a modification that would require labeling. Labels applied prior to September 30, 2011 are acceptable if they contain the available incident energy or required level of PPE.

However, OSHA’s general duty clause for hazard warning may apply here. Should the equipment be modified or upgraded in any way, then a label must be affixed. In fact, an OSHA representative has stated that even changing a fuse or circuit breaker could be considered a modification that would require labeling. Labels applied prior to September 30, 2011 are acceptable if they contain the available incident energy or required level of PPE.

From a safety perspective, the hazard is the same regardless of when the equipment was installed. Consequently, most employers are simply labeling all the appropriate equipment, regardless of when it was installed.

The NEC requirement states that the marking must be in a location that is clearly visible to qualified persons before they begin work. Typically, the label is placed outside the panel or enclosure door. In some cases,companies choose to put the label inside the door to protect it from harsh environments; however, this should only be done if the door must be opened (allowing the label to be seen) in order to remove the panel face or enclosure. The key point is that the label should be easily noticeable by workers before they may be exposed to any potentially dangerous live parts.

What Needs to Appear on the Label?

Neither the NFPA 70E nor the NEC requirements specify whether to use a “Danger” or “Warning” header; however, NFPA 70E does recommend identifying those situations in which there is a hazard to the worker. A commonly used guideline is to use a red “Danger” header when the voltage is over 600 volts or when the incident energy is over 40 cals/cm2. Many employers have also standardized to using the “Danger” signal word to indicate a situation where serious injury or death WILL occur. If it is less than that threshold, an orange “Warning” header is used. The employer has the final decision on which words appear on the labels, but it is imperative that consistency be maintained on all the labels throughout the facility.It is also important to note that arc flash labels must be able to withstand their usage environment. This means that the print should not fade and the adhesive should be aggressive enough to avoid peeling. When necessary, an over laminate should be applied to protect the printed surface from harsh chemicals and exposure to sunlight.

standardized to using the “Danger” signal word to indicate a situation where serious injury or death WILL occur. If it is less than that threshold, an orange “Warning” header is used. The employer has the final decision on which words appear on the labels, but it is imperative that consistency be maintained on all the labels throughout the facility.It is also important to note that arc flash labels must be able to withstand their usage environment. This means that the print should not fade and the adhesive should be aggressive enough to avoid peeling. When necessary, an over laminate should be applied to protect the printed surface from harsh chemicals and exposure to sunlight.

How Many Labels per equipment?

Neither the NFPA 70E nor the NEC requirements specify whether to use a “Danger” or “Warning” header; however, NFPA 70E does recommend identifying those situations in which there is a hazard to the worker. A commonly used guideline is to use a red “Danger” header when the voltage is over 600 volts or when the incident energy is over 40 cals/cm2. Many employers have also

standardized to using the “Danger” signal word to indicate a situation where serious injury or death WILL occur. If it is less than that threshold, an orange “Warning” header is used. The employer has the final decision on which words appear on the labels, but it is imperative that consistency be maintained on all the labels throughout the facility.

It is also important to note that arc flash labels must be able to withstand their usage environment. This means that the print should not fade and the adhesive should be aggressive enough to avoid peeling. When necessary, an over laminate should be applied to protect the printed surface from harsh chemicals and exposure to sunlight.

How Many Labels per equipment?

A frequently asked question is how many labels are enough? Obviously if one is good, more is better – right? This philosophy has both positive and negative aspects that must be considered. The more labels used the higher the visibility factor. However, too many labels clutter the objective and cause workers to ignore the warning.For the MCC above, a simple one-word “warning” label was used without providing specific PPE, boundary information, or hazard levels. This minimizes clutter, however, if you take a step back and see 50-75 of these labels the clutter becomes obvious. The clutter is even more prevalent and confusing if the standard AFH information is included on the labels. The worker looking at the MCC must then determine- Which label is important?

- If the labels are different, what information applies to this task?

- How do I react to these circumstances?

A frequently asked question is how many labels are enough? Obviously if one is good, more is better – right? This philosophy has both positive and negative aspects that must be considered. The more labels used the higher the visibility factor. However, too many labels clutter the objective and cause workers to ignore the warning.

For the MCC above, a simple one-word “warning” label was used without providing specific PPE, boundary information, or hazard levels. This minimizes clutter, however, if you take a step back and see 50-75 of these labels the clutter becomes obvious. The clutter is even more prevalent and confusing if the standard AFH information is included on the labels. The worker looking at the MCC must then determine

- Which label is important?

- If the labels are different, what information applies to this task?

- How do I react to these circumstances?

Examples

This section provides multiple labeling examples for different types of electrical equipment, which can be modified or extrapolated to fit your system. For some equipment types, multiple options will be provided.

This section provides multiple labeling examples for different types of electrical equipment, which can be modified or extrapolated to fit your system. For some equipment types, multiple options will be provided.

Panels

Panels are typically of box construction with a fixed backing plate attached to a beam/ wall mounted. The front of the panel, which provides opening access, is bolted in place. The front cover typically has a hinged opening, which allows viewing and operation of the breakers. For standard 42 circuit

Panels are typically of box construction with a fixed backing plate attached to a beam/ wall mounted. The front of the panel, which provides opening access, is bolted in place. The front cover typically has a hinged opening, which allows viewing and operation of the breakers. For standard 42 circuit

lighting panels, the typical labeling procedure is one label on the main cover, top center. See Figure-1.

lighting panels, the typical labeling procedure is one label on the main cover, top center. See Figure-1.

Panel boards

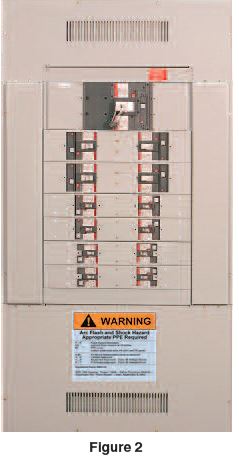

Panel boards, sometimes called distribution panel boards (DPB), or distribution boards are larger than a standard panel and may range from 400-1200A. They are typically standalone, but smaller units may be wall or beam mounted. Larger units may be accessible front and back side via bolted covers. For standard DPB’s, typical labeling procedures is one label on the main cover, top center. For the example shown in Figure-2, the label was moved to the bottom to prevent covering the cooling vents. Panel boards, do not have isolated and barrier protected main breakers unless specially ordered and should always have only one label.

Panel boards, sometimes called distribution panel boards (DPB), or distribution boards are larger than a standard panel and may range from 400-1200A. They are typically standalone, but smaller units may be wall or beam mounted. Larger units may be accessible front and back side via bolted covers. For standard DPB’s, typical labeling procedures is one label on the main cover, top center. For the example shown in Figure-2, the label was moved to the bottom to prevent covering the cooling vents. Panel boards, do not have isolated and barrier protected main breakers unless specially ordered and should always have only one label.

Dry Type Transformers

Dry type transformers typically have a bolted on face plate section with exposed terminals behind the face plate. Since this is the main access point, it is usually not necessary to label the other sides.Figure-3

Dry type transformers typically have a bolted on face plate section with exposed terminals behind the face plate. Since this is the main access point, it is usually not necessary to label the other sides.Figure-3

Variable Frequency Drives,and Control Cabinets

Variable frequency drives and control cabinets are typically hinged front opening units with an open, exposed incoming main breaker. The incoming breaker or fuse is typically not isolated or barrier protected from the other sections and therefore cannot be used for AFH protection. Like other cabinets, one “worst case” label is typically sufficient. See Figure-4.

exposed incoming main breaker. The incoming breaker or fuse is typically not isolated or barrier protected from the other sections and therefore cannot be used for AFH protection. Like other cabinets, one “worst case” label is typically sufficient. See Figure-4.

Variable frequency drives and control cabinets are typically hinged front opening units with an open, exposed incoming main breaker. The incoming breaker or fuse is typically not isolated or barrier protected from the other sections and therefore cannot be used for AFH protection. Like other cabinets, one “worst case” label is typically sufficient. See Figure-4.

exposed incoming main breaker. The incoming breaker or fuse is typically not isolated or barrier protected from the other sections and therefore cannot be used for AFH protection. Like other cabinets, one “worst case” label is typically sufficient. See Figure-4.

Switchboards and Switch Gear

Switchboards and Switch gear are the standard for low voltage distribution equipment. Switch gear by definition has isolated and barrier protected cubicles, rack-in air frame breakers/switches, and isolated bus. Switchboards may have similar attributes but will most likely be equipped with molded case or insulated case breakers, or fuses in non-isolated cubicles with non-isolated bus work. By special order, the main breaker/switch can be isolated, enhancing arc flash protection.

For a typical 4 section or less switch gear lineup, only one label (worst case) on the front side is necessary. For longer sections additional labels can be applied every 5-10 feet. Since both front and back-side switch gear covers are hinged, the back-side covers should also be labeled.For switchboards, the back-sides are typically open exposed bus with bolted covers, which should prevent access. Labeling should be optional since access is not easily obtained.

Switchboards and Switch gear are the standard for low voltage distribution equipment. Switch gear by definition has isolated and barrier protected cubicles, rack-in air frame breakers/switches, and isolated bus. Switchboards may have similar attributes but will most likely be equipped with molded case or insulated case breakers, or fuses in non-isolated cubicles with non-isolated bus work. By special order, the main breaker/switch can be isolated, enhancing arc flash protection.

For a typical 4 section or less switch gear lineup, only one label (worst case) on the front side is necessary. For longer sections additional labels can be applied every 5-10 feet. Since both front and back-side switch gear covers are hinged, the back-side covers should also be labeled.

For switchboards, the back-sides are typically open exposed bus with bolted covers, which should prevent access. Labeling should be optional since access is not easily obtained.

Do’s and Don’ts of AFH labeling

Do’s

- Do label “WORST” case energy or PPE level. Consider all possible modes of operation.

- Do label per ANSI Z535.4

- Do label using only one color, Orange for Warning or Red for Danger.

- Do standardize on only one working distance – preferably 18 inches for all labels in a facility.

- Manage down PPE levels using work permits stating increased distances based on work task and proper safety procedures.

- Label to warn of potential danger, not for the purpose of working on the equipment.

- Do use common sense in your hazard labeling.

- Do implement NFPA 70E Article 130.1 work permit requirements for all energized work even if a label is present.

- Do label “WORST” case energy or PPE level. Consider all possible modes of operation.

- Do label per ANSI Z535.4

- Do label using only one color, Orange for Warning or Red for Danger.

- Do standardize on only one working distance – preferably 18 inches for all labels in a facility.

- Manage down PPE levels using work permits stating increased distances based on work task and proper safety procedures.

- Label to warn of potential danger, not for the purpose of working on the equipment.

- Do use common sense in your hazard labeling.

- Do implement NFPA 70E Article 130.1 work permit requirements for all energized work even if a label is present.

.jpg)

No comments:

Post a Comment