Tuesday, 11 November 2025

Friday, 25 April 2025

Tuesday, 25 March 2025

Sunday, 23 March 2025

Sunday, 2 March 2025

Thursday, 2 January 2025

Rigging Always Plays A Major Role At Workplace

Rigging Always Plays A Major Role At Workplace

Rigging is the most imperative aspect of lifting loads during various crane operations. Even with the safest crane and equipment, rigging always plays a major role in ensuring smooth crane operations and improved security.Individuals responsible for carrying out rigging should be

experienced professionals, who thoroughly understand the rigging and its

procedures. Safety is the most significant aspect of rigging. After all, the

main purpose of rigging is to help reduce or eliminate injuries and accidents.

The following are the six most important rigging hardware used for crane operations.

Rigging Hooks

Hooks used in rigging are designed to lift heavy objects and

eliminate slippage, depending on the materials being moved. Rigging hooks are

made of forged alloy steel and chosen based on safe weight load indication and

have multiple types: sorting, eye, clevis grab and choker. Hooks are available

based on throat, or hook opening, size and range from 5/8″ to 1 17/32″.

Shackles

Loads exceeding 6,000lbs may require shackles, which are

forged with alloy pins and can accommodate loads up to 11,000lbs. Shackles are

available in sizes from 3/16″ to 2 ½” and come in anchor or chain types. Screw

pin, round pin and safety type anchor and chain shackles are available.

Eye Bolts & Steel Nuts

Selection of eye bolts depends on angle loading factors,

typically 30, 60 or 90 degrees. Eye bolts are commonly used for looping cable

or wire and thus must be strong enough to accommodate the required load.

Different types of straight and shoulder eye bolts are used in rigging

equipment including nut, eye, machinery and screw which vary in size from 1/4″

to 2″. Nuts are used in conjunction with eye bolts and are made of steel. The

dimensions chosen for both eye bolts and nuts are dependent upon the load’s weight,

shape and specifications.

Wire Ropes

Large materials can be moved with wire ropes and slings. The

most commonly used wire ropes are fortified by multiple strands of stainless

steel or carbon steel wire ropes arranged in a helix pattern. Wire ropes can be

coated or not, galvanized and are available in multiple specifications. The

most common classifications are 6×26, 7×7 and 7×19.

Synthetic Slings

Used in conjunction with wire ropes, slings are available in

endless and eye-and-eye styles. Synthetic material is used to create the sling

itself while eye-and-eye slings feature metal triangular ends with or without a

choker. Some eye-and-eye slings do not have metal triangle loops; instead, they

feature a flat or twisted eye that is also made of synthetic material.

Pulleys & Blocks

A requirement for very heavy loads, lifting blocks and

pulleys mitigate weight to simplify the process of maneuvering heavy objects.

The most common type of block is the snatch block, but other options include

tilt-up blocks and logging blocks. Wire rope is typically used with blocks.

Blocks are easy to deploy and available in multiple sizes to accommodate up to

30 tons. Pulleys, available in single and double types, are often used with

synthetic rope and typically carry lighter loads than lifting blocks. Pulley

selection is based on rope, frame and sheave size.

Saturday, 31 August 2024

RH : Material Hoisting - Mobile Crane

Material Hoisting - Mobile Crane

Many incidents were reported while using Hydra type cranes as the stability is less during operations.

Below are some safety tips related to crane operations.

- Cranes are to be operated only by qualified and trained personnel.

- All equipment used shall have test certificates & in good condition (Crane, Forklift, etc.) Site in-charge / Engineer must inspect the crane visually before use.

- Ensure that crane is on a firm/stable surface and level & outriggers are fully extended.

- Workers must not ride on a load or hook.

- Barricade the working area / accessible areas within the crane's swing radius.

- Pathway clear for the movement and has sufficient illumination.

- Watch for overhead electric power lines and maintain at least a 10- foot safe working clearance from the lines.

- Tools and tackles used (Slings, D-Shackles, Trolleys, Hydraulic Jacks, etc.) shall have test certificates

- Inspect all rigging tools and tackles prior to use.

- Be sure to use the correct load chart for the crane's current configuration and setup, the load weight and lift path.

- Do not exceed the load chart capacity while lifting.

- Raise load a few inches, hold, verify capacity/balance, and test brake system before proceeding.

- Do not move loads over people.

- Do not walk under suspended loads.

- Be sure to follow signals (by the aid of signalman) and manufacturer instructions while operating cranes.

RH : Importance of Web Sling Inspection

Importance of Web Sling Inspection

Hoisting and rigging is a vital and common work task in many workplaces. Slings are devices used to lift and move items mechanically. At times, they can be put under great stress which can lead to damage.

This safety talk identifies common sling failures and covers best practices when inspecting these devices to ensure a safe working experience.

Common Web Sling Failures

- Slings can break apart when overloaded.

- Slings can stretch and fray over time.

- Slings exposed to cutting and grinding, along with welding splatter, can become burned and compromised.

- Slings exposed to chemicals can deteriorate.

- Slings that are continually wet or left in direct sunlight for extended periods can rot and disintegrate.

Inspection of Web slings

- Slings should be inspected for burnt marks and unraveled threads.

- When inspecting slings, if red nylon fibers are visible, the sling should be removed from service.

- Slings that are discolored and stiff should be removed from service as that is an indicator of chemical exposure.

- Slings that are rigid and unable to move freely show signs of excessive UV exposure.

- Threads that frayed and rotted indicate the sling should be removed from service.

- Slings that are missing tags complete with loading capacity are no longer compliant and should not be used in the workplace.

- Slings should be inspected before use. Inspection should occur throughout the workday if the sling is being used over and over.

- Slings should also be inspected monthly and annually as part of a comprehensive safety inspection process.

Summary

Inspecting slings is a good practice that allows user to identify possible issues with the sling prior to use.

If issues are identified, it is vital to stop work and get a functional sling for the work task at hand. A simple inspection may make all the difference in preventing property loss or injury.

RH : Powered Winches Machines and Accosiated Hazards

Powered Winches Machines and Accosiated Hazards

At Construction sites uses of Powered Winch Machine are common, These are basically machines that pull fibre or wire rope. They are often described as boomless cranes.Advantages of using winch machine instead of cranes can include:

- Lower operating costs

- The equipment is lighter and more portable

- The smaller size permits use in tight spots—they’re ideal for use inside buildings.

Winch machine can be used for both hoisting (vertical lift) and hauling (horizontal or vertical incline pulls). They may be powered hydraulically, electrically, by compressed air or by an internal combustion engine. The most common winch seen in construction are electric winches (for light lifting and pulling), and air-powered winches (for heavier loads). Wire rope is used for heavy applications while fibre rope is used for lighter applications.

Examples of winch use in construction include pulling electrical cables, moving heavy machinery, lifting vessels, and installing structural steel.

Winch machine are often used with other rigging attachments. The most common attachments include snatch blocks, sheaves, and rollers. Snatch blocks and sheaves are used to change the direction of pull while rollers are used to support the load.

Winch machines operations involve rigging. Because of this, the hazards associated with rigging operations will also be present while operating a winch machine. A very important element in winch operation safety is preplanning. Many difficulties can occur during a lift, such as an unexpected shift of the load’s centre of gravity. Planning for an adequate safety factor in, for example, the rigging components and anchor points, will avoid failures and potential catastrophe during winch use. Thorough planning of a lift will help you prepare for difficulties that may arise.

Hazards associated with tugger operation

The kinds of hazards a worker is likely to be exposed to during tugging operations are similar to those in rigging applications. Check for the following hazards, as well as conditions that can create hazards:

- Poor communication.

- Lack of training.

- Overloading.

- Failure of tugger and rigging assembly.

- Fall hazards.

- Failure of anchorage points of the winch or rigging components.

- Shifting or other movement of the tugger or point of anchorage when under load.

- Brake failure when under load.

- Unexpected movement of the equipment which can strike or crush a worker handling the load.

- The moving drum and sheaves which can pinch or crush a worker’s hand.

- Loose clothing or jewellery caught in drum or sheaves.

- Electrical hazards when using electrically powered winches.

- Carbon monoxide from combustion by-products in confined spaces.

- Fire or explosion (if operated in an area of combustible products).

- Exposure to hydraulic fluid from hoses breaking or leaks.

- Improper purging of hydraulic lines.

- Rope coming off the drum.

- Area not isolated from other workers or public during hoisting or hauling.

A winch machine must generate enough pull through the load line to lift, move, or hold the load and any associated rigging. In addition to this pull, there is also stored “potential” energy in the system. A failure in the rigging system can result in a violent whipping of the lift line due to release of this stored energy, and the release of the load. It's of paramount importance to ensure that all rigging and all points of anchorage are able to safely handle all loads, or all potential loads, to which they might be subjected.

All rigging components and points of anchorage may be subjected to forces greater than the weight of the load. It should to check and certified at regualr intervals by competent person and records to be maiantained as per local country requirements.

RH : Rigging Hardware & Its Failure

- Rigging is only as strong as its weakest link. Workers’ lives depend on the strength of that link.

- It doesn’t matter what safe working load is stamped on a hook if the hook is cracked and twisted or opening up at the throat. It can’t deliver its full rated capacity.

- Inspection is vital in rigging and hoisting.

- Rigging hardware must have enough capacity for the job. Only load - rated hardware of forged alloy steel should be used for hoisting. Load - rated hardware is stamped with its working load limit or WLL.

- Adequate capacity is the first thing to look for in rigging hardware. For hoisting, the design factor must be 5 to 1.

- Once the right hardware has been chosen for a job, it has to be inspected regularly as long as it’s in service.

- Cracks:- Inspect closely —some cracks are very fine.

- Missing parts:- Make sure that parts such as clips, and cotter pins in shackle pins are still in place.

- Stretching:- Check hooks, shackles, and chain links for signs of opening up, elongation, and distortion.

- Stripped threads:- Inspect turnbuckles, shackles, and cable clips

- Check for wear on saddle.

- Check that original parts are in place and in good condition.

- Check for cracks.

- Check for proper size of the wire rope.

- Check for wear and cracks on saddle and pin.

- Check that pin is straight and properly seated.

- Check that legs of shackle are not opening up.

- Check for wear, twisting, and cracks.

- Make sure that hook is not opening up.

- Check for cracks and bends.

- Check rods for straightness and damage to threads.

Rigging Failure

Every year workers lose their lives as a result of improper rigging or rigging failure that allowed a load to fall while being hoisted. Some deaths occur when the load slips from the rigging, when the rigging breaks and allows the load to fall, and when the load breaks into pieces and falls while being lifted.

Always exercise caution when working around:

- Inspect all rigging prior to use to minimize the possibility of rigging failure.

- Look for hazardous conditions such as wire rope deformation, strain, binding, or kinking.

- Do not wrap hoist lines around the load.

- Know the rated capacities of rigging and slinging and use the proper size.

- Ensure that loads are rigged to minimize the potential for dropped loads.

- Do not exceed the load chart capacity while making lifts.

- Determine a safe location to stand to avoid being struck by the load if rigging fails, or the load shifts while making lifts.

RH : Rigging Safety Rules & Tips

Rigging Safety Rules & Tips

- Be sure to establish the weight of the load.

- Determine the proper type of hitch based on the type of load.

- Understand the relationships between angles and tension as they pertain to slings and hardware. If you don’t understand the relationships, or if you have any questions, check with your supervisor before you proceed.

- Make sure that you select the right sling for the job based on the type of load to be lifted.

- Also, select the right hardware based on the type of load and the type of sling or slings that will be used for the lift.

- Inspect each sling before you use it. Never use a defective sling. Take defective slings out of service immediately and follow your company’s procedure for handling defective equipment.

- Inspect all rigging hardware before you use it. Never use defective hardware.Take defective hardware out of service immediately and follow your company’s procedure for handling defective equipment.

- As you rig the load, protect slings from cuts and tears.

- Determine the load’s center of gravity.

- Pay close attention to detail at the time of the lift.

- Never tie two or more slings together.

- Always connect two slings with an appropriate-sized shackle.

- Never attach a sling directly to a lifting lug. Always use a shackle.

- Likewise, never run a sling through a set of lifting lugs or eye-bolts. Doing so creates too much tension on the lugs or eye-bolts.

- Never choke below the threads on synthetic web slings.

- Take wire rope slings out of service immediately if they become defective. A wire rope is defective if there are five or more broken wires in one rope lay and/or three or more broken wires in one strand of one rope lay, (a rope lay is the length along the rope where one strand makes a complete revolution around the rope).

- Some companies have established a policy that wire rope is defective when a single wire breaks. Check with your supervisor about your company’s policy before using wire rope slings.

- “Never saddle a dead horse.” When using wire rope clips be sure to attach the wire rope clips with the inside curve of the U -bolt up against the very end(dead end) of the wire, and the inside of the U-bolt clip (saddle) up against the live end of the wire.

- Spotters or signalers to guide the operator.

- Two-way radios for clear instructions.

- Pre-lift planning to identify potential hazards.

- Never allow a synthetic sling to bunch up on a shackle.

- Always use the right size shackle for the job. For example, a 1 inch shackle is too small to use with a 1 ½ inch wire rope sling. However, a 2 inch shackle works safely with a 1 ½ inch wire rope sling.

- Never make a shackle to shackle connection.

- Be sure to use a safe shackle orientation. Don’t allow the inside loop of a wire rope sling to place tension on a shackle pin directly where the pin screws into the shackle or directly where the pin comes through the hole on the opposite side of the shackle. Doing so would place too much tension on the shackle ears.

- Never orient two slings in a shackle so that they would pull the shackle in opposite directions that are parallel to the shackle pin.

- Be sure not to orient a shackle/sling on a shackle pin in a manner that could result in the shackle pin becoming unscrewed during the lift.

- Make sure that you choose the right size sling/sling loop based on the size of the crane or derrick hook.

- Be sure not to “point load” crane or derrick hooks. The rated capacity of the hook decreases as the angle increases and the load moves out away from the center of the hook.

RH : Rigging - Fiber Ropes, Knots and Hitches

Rigging - Fiber Ropes, Knots and Hitches

- Slings for hoisting materials.

Hand lines for lifting light loads.

- Taglines for helping to guide and control loads.

Characteristics:

Polypropylene:

Nylon:

Polyester:

Inspection:

and the elasticity or “life” remaining in the rope.

and clean as when it was new. Check for broken yarns, excessively loose strands and yarns, or an

accumulation of powdery dust, which indicates excessive internal wear between strands as the

rope is flexed back and forth in use.

thimble (Figure 2.1). Ensure that all splices are in good condition and all tucks are done up (Figure

2.2).

Working Load Limit:

- Let’s calculate the WLL of a chain or gin wheel rated at 1000 pounds with a manufacturer’s DF of 3.

with the Construction Regulation, it can safely lift a maximum capacity of 600 pounds.

Fiber Rope Selection:

the working load (WL) by the SF. The minimum breaking strength (MBS) is the force at which a new rope will break.

The SF, if greater than the DF, adds an additional layer of safety to meet the requirements of users

and regulators. Together, these added layers of safety provide protection above the MBS to account for reduced capacity due to

- wear, broken fibers, broken yarns, age

- variations in construction size and quality

- shock loads

- minor inaccuracies in load weight calculations

- variances in strength caused by wetness, mildew, and degradation

- yarns weakened by ground-in or other abrasive contaminants.

Let’s calculate the WLL of a rope to lift a WL of 250 pounds.

Care:

- To unwind a new coil of fiber rope, lay it flat with the inside end closest to the floor. Pull the inside end up through the coil and unwind counterclockwise.

- After use, recoil the rope clockwise. Keep looping the rope over your left arm until only about 15 feet remain. Start about a foot from the top of the coil and wrap the rope about six times around the loops. Then use your left hand to pull the bight back through the loops and tie with a couple of half hitches to keep the loops from uncoiling ( Figure 2.5).

- Remove kinks carefully. Never try to pull them straight. This will severely damage the rope andreduce its strength.

- When a fibre rope is cut, the ends must be bound or whipped to keep the strands from untwisting. Figure 2.4 shows the right way to do this.

Storage:

- Store fiber ropes in a dry cool room with good air circulation – temperature 10-21°C (50-70°F) humidity 40-60%.

- Hang fiber ropes in loose coils on large diameter wooden pegs well above the floor (Figure 2.5).

- Protect fiber ropes from weather, dampness, and sunlight. Keep them away from exhaust gases, chemical fumes, boilers, radiators, steam pipes, and other heat sources.

- Let fiber ropes dry before storing them. Moisture hastens rot and causes rope to kink easily. Let a frozen rope thaw completely before you handle it. Otherwise fibers can break. Let wet or frozen rope dry naturally.

- Wash dirty ropes in clean cool water and hang to dry.

Use:

- Never overload a rope. Apply the design factor of 5 (10 for ropes used to support or hoist personnel). Then make further allowances for the rope’s age and condition.

- Never drag a rope along the ground. Abrasive action will wear, cut, and fill the outside surfaces with grit.

- Never drag a rope over rough or sharp edges or across itself. Use softeners to protect rope at the sharp comers and edges of a load.

Avoid all but straight line pulls with fiber rope. Bends interfere with stress distribution in fibers.

- Always use thimbles in rope eyes. Thimbles cut down on wear and stress.

- Keep sling angles at more than 45°. Lower angles can dramatically increase the load on each leg (Figure 1.6). The same is true with wire rope slings.

- Never use fiber rope near welding or flame cutting. Sparks and molten metal can cut through therope or set it on fire.

- Keep fiber rope away from high heat. Don’t leave it unnecessarily exposed to strong sunlight, which weakens and degrades the rope.

- Never couple left-lay rope to right-lay.

- When coupling wire and fiber ropes, always use metal thimbles in both eyes to keep the wire rope from cutting the fiber rope.

- Make sure that fiber rope used with tackle is the right size for the sheaves. Sheaves should have diameters at least six – preferably ten – times greater than the rope diameter.

Knots:

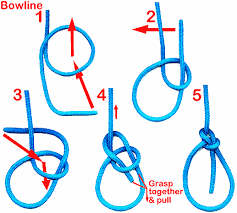

Bowline:

Pipe Hitch:

Reef or Square Knot:

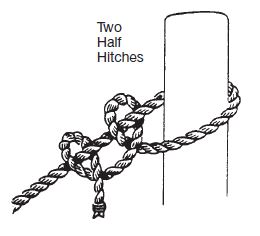

Two Half Hitches:

Running Bowline:

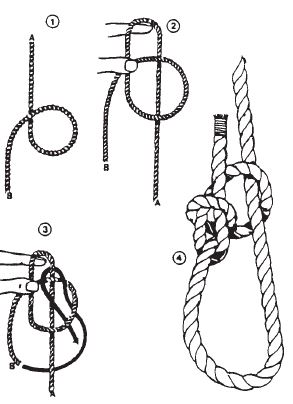

Running Bowline:

- Hold the loop with your thumb and fingers and bring the standing part of the rope back so that it lies behind the loop

- Take the end of the rope in behind the standing part, bring it up, and feed it through the loop

- Pass it behind the standing part at the top of the loop and bring it back down through the loop.

Figure-Eight Knot:

It is also larger, stronger, and does not injure the rope fibers. The figure-eight knot is useful in preventing the end of a rope from slipping through a block or an eye.

- Bring the end around and over the standing part

- Pass the end under and then through the loop

- Draw up tight.

Convey the Right Safety Information About Conveyors

www.safetygoodwe.com Convey the Right Safety Information About Conveyors Employees should be familiar with these basic ...

-

www.safetygoodwe.com Rigging Always Plays A Major Role At Workplace Rigging is the most imperative aspect of lifting loads ...

-

www.safetygoodwe.com Topic: Safety Article Reporting Safety Observation ReportingSafety observation is a process that involves employ...

-

www.safetygoodwe.com Elevator Safety Tips Though elevators are one of the safest forms of transportation, following simple guidelines can...

.jpg)